What does Conformity of Production mean for vehicle manufacturers and suppliers?

CoP refers to the procedures and arrangements for “conformity of production”. However, the requirement for CoP is not only found in legislation with the Framework Regulation (EU) 2018/858, which has been mandatory since 01.09.2020. However, the specifications and requirements have been specified.

What does it mean?

In most countries, regions or economic communities worldwide, an approval procedure for vehicles and vehicle parts has been established that is similar to the procedure in the EU or according to UN/ECE.

This means that “one” test sample of the vehicle or component subject to approval is evaluated by the approval authority with regard to compliance with the legal requirements. Only after a positively completed evaluation, an approval is granted and the serial production or the placing on the market is allowed.

What is a “component”?: A component in this case is not necessarily a component such as a brake pad, a door handle or a steering wheel. The decisive factor is whether an individual legal act describes a specific function or design that must be fulfilled.

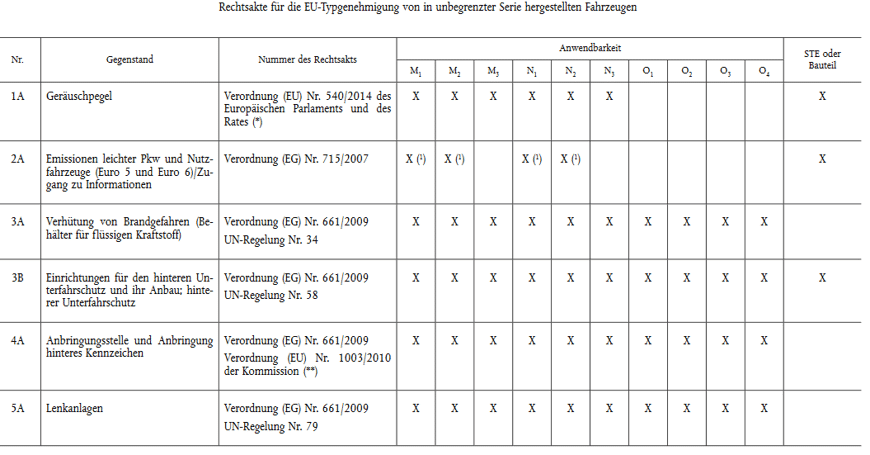

A list of the individual acts can be found in the Framework Regulation (EU)2018/858 in Annex II

Taking a headlamp as an example, you can imagine that the shape of the headlamp is not subject to any specific criteria (apart from sharp edges and the like). Described are, for example, the light color, light brightness and light distribution.

Many functions described in the legal acts cannot be performed by a single component. These are typically recorded or circumscribed as a system in the respective permit.

If the manufacturer of a component, a system, an autonomous technical unit or a complete vehicle has received a corresponding approval (of the type) from the authority, however, this does not end his obligation towards the legislator.

The commitment to CoP-P begins with the start of series production.

CoP-P defines the tests that must be performed on products to be taken from the current series to demonstrate that the products comply with the approved status.

In other words, what was tested as part of the type test must be reproduced. If this can be a destructive test in the case of a type test, dismantling work (in the case of visual inspections) or damaging tests must be avoided, since the rules for selecting samples from production stipulate that products are selected at random for these verifications, i.e. they are typically products intended for delivery to the customer.

Incidentally, the increased mileage of a “CoP vehicle” at delivery is to be tolerated if the increased mileage is due to compliance with legal requirements (such as CoP). There is no legal regulation that sets a limit for a new car in terms of mileage (to 100km, for example). However, there is case law that could grant customers a conversion in the case of high mileage.

Learn everything you need to know or always wanted to know about CoP in the CoP basic training and CoP advanced training. In addition to the requirements regarding CoP- P, you will also learn all about CoP- Q. You will also learn to understand what distinguishes CoP testing from quality testing and whether or why a clear separation of quality assurance and CoP can help save costs in the 6- or 7-figure range.

I look forward to meeting you at one of my open training sessions.

For groups of 5 or more people, in-house training courses can also be booked as video or classroom training. Please ask for a non-binding offer.